3DLac - adhesive for 3D printing put to the test with PLA

What is 3DLac?

3DLac is an adhesive that you spray on your 3D printing surface to help the printed part stick to the bed and prevent warping. It works well with PLA, ABS, flexible filaments and more.

But how well does it work and is it useful?

We put 3DLac to the test with PLA from Materio3D to see exactly how strong the spray is.

In the future, we will experiment with 3DLac with other materials and compare with different adhesion methods.

Testing Method

I wanted to make a simple test that does not take too much time to print, but will also warp. I created a long rectangular block so there would be a decent amount of natural warping. The block is 19.2 cm x 2.6 cm x 1 cm.

All parts were printed on our Ultimaker 3 extended and sliced with Cura 3.3.1. I made three iterations while only changing the bed temperature.

Quick note : Ultimaker 3 extended has a glass print bed.

Print settings:

220°C nozzle, 100% infill, 70 mm/s printing speed and 0.2 mm layer height.

Test 1 - Bed Temperature: 60°C

Picture on top is without 3DLac and the picture below is with the spray.

The difference is barely visible with this print, but there is minimal warping for the stick printed with no 3DLac, whereas the one with the adhesion spray is perfect.

I put both prints next to each other to show you the difference between them. You can see the small amount of warping on the corners of the print on top which was printed without 3DLac.

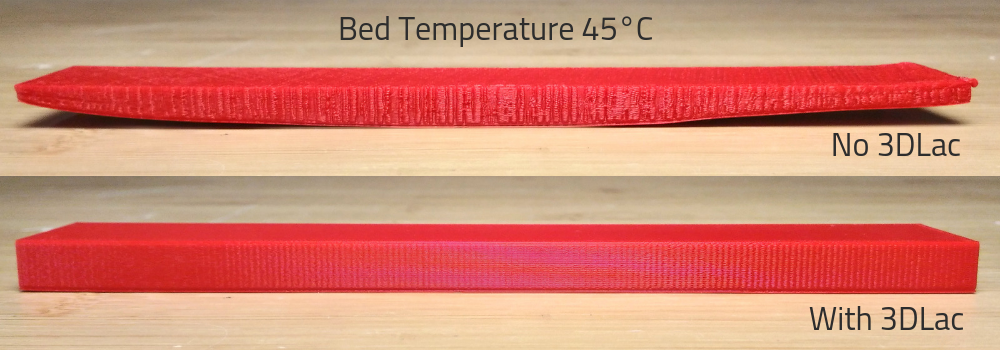

Test 2 - Bed Temperature: 45°C

All other slicing settings remained the same from one print to the next, I only change the bed temperature.

Picture on top is without 3DLac and the one below is with.

I stopped the print with no 3DLac as it was becoming too ugly. On the other hand, the stick with 3DLac printed perfectly. I did not do a comparison for this print as the difference is obvious.

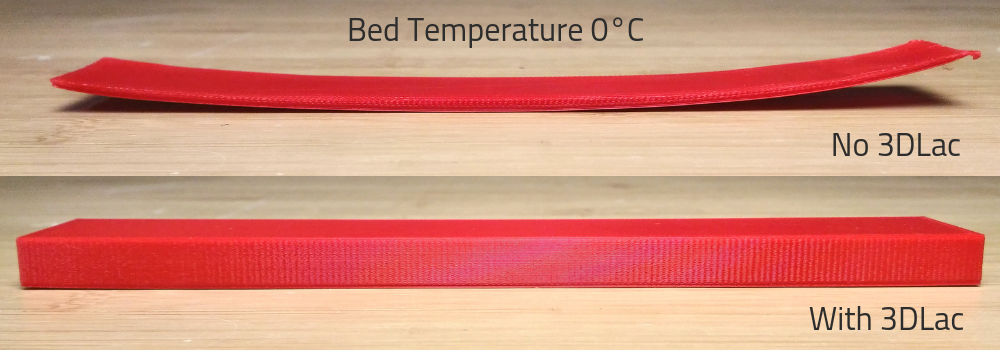

Test 3 - Bed Temperature: 0°C

It might be an excessive test, but I wanted to push the test to the max with the printing bed at 0°C. In our store, the ambiance temperature is around 25°C.

Picture on top is without 3DLac and the picture below is with.

Printing without a heated bed and no adhesive caused a failed print, something that I expected. However, I did not expect a close to perfect print using 3DLac and an unheated bed. There is a minimal amount of warping.

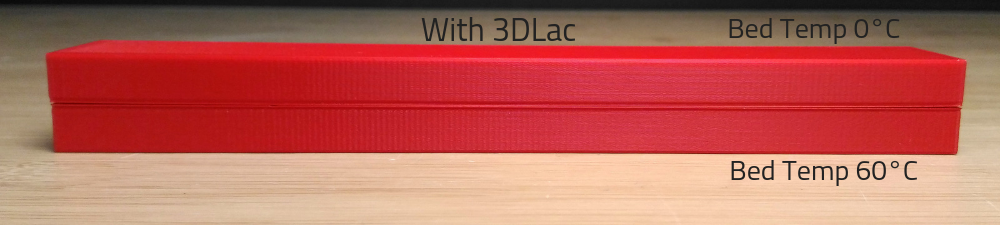

I compared the print with the bed at 60°C with 3DLac against the one printed at 0°C with 3DLac. You can see that the corners of bottom part, the one printed at 0°C, warped slightly.

The Verdict

3DLac is a strong adhesive spray that work very well with PLA.

- Nathan Orfin